- 15

- Nov

Comparison and analysis of roasted red light bulb and natural red light bulb

Infrared bulb according to the glass shell materials is divided into hard materials and soft materials, the expansion coefficient of the soft materials glass shell is high, the expansion coefficient of the hard materials glass shell is low. Generally speaking, the lower the expansion coefficient of the glass shell, the safe the bulb is. Especially in low temperature and humid environment, the glass shell is not easy to burst when it meets water. Therefore, the bulb produced by hard glass shell has a higher safety coefficient than that produced by soft glass shell.

Usually, the expansion coefficient of the glass shell of the soft bulb is between 85 and 90, while that of the standard hard bulb is between 39 and 41. However, the expansion coefficient of the R125 semi-roasted red glass shell is between 46 and 48, and the explosion-proof effect is relatively poor compared to the standard hard glass shell, which is caused by the limitations of the traditional red baking process. If the expansion coefficient is too small or the expansion coefficient is too large, the color of the red bulb won’t be achieved, Based on this, our company adopts a new formula and new production process to develop a new glass shell, the expansion coefficient is about 40, and the color and bulb rendering effect of the glass shell are better than the traditional semi-baked red bulb.

Formulate and process description.

- The traditional roasted red bulb lamps is coated with chemicals, coating containing silver nitrate, copper sulfate and kaolin on the top of the glass shell, after high temperature baking, annealing color forming, and then after manual cleaning to remove the residual powder coating on the top of the glass shell.

- Preparing the red glass shell materials: according to the proportion in the glass shell raw materials such as quartz sand and add various kinds of metal elements, stirring to mix, and then melt into liquid glass trough furnace, and then send trough the discharging mouth to the glass shell mold blowing to shape, to form the finished glass shell, and annealing in the 30 meters long tunnel of annealing furnace. The secondary color appears on the glass shell during this produces, and finally get the natural red glass shell out of the tunnel.

The following is a comparative analysis of the advantages and disadvantage of the half-roasted red light bulb and the natural red light bulb.

- Comparison of processes: due to certain hazard of some chemical raw materials in the backing red bulb formula, it has high requirements for safety protection of workers, meanwhile, the cleaning wastewater in the later stage of backing red glass shell has certain environmental damage. Therefore, the production disadvantages of the traditional backing red glass shell are becoming more and more obvious. The natural red glass shell belongs to the one-time molding, completely avoid the risk caused by environmental pollution, the market prospect is optimistic.

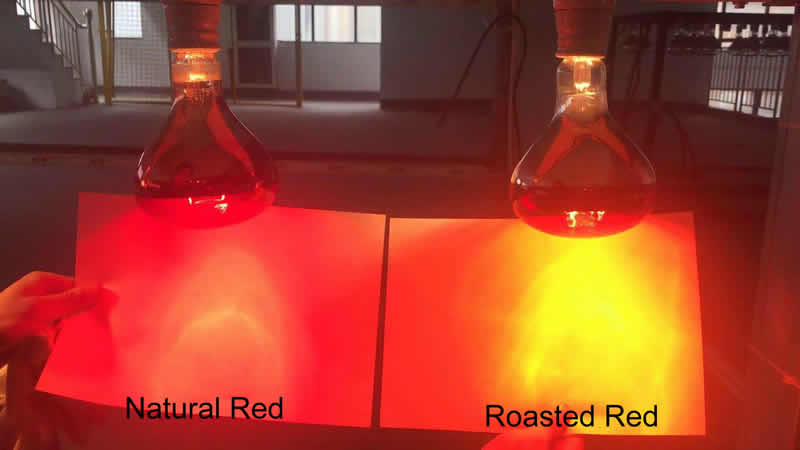

- Appearance comparison:

This natural red glass shell is more pure red, roasted red glass shell is slightly yellow, this is mainly because the natural of color reaction is not the same, coating uniformity and coating thickness will affect the color effect in the coating process for the roasted red glass bulbs.

- Bulb color contrast.

The roasted red light bulb shell is slightly yellow, resulting in yellow light won’t be filtered out by the glass shell, so the light spot slightly yellow, and the natural red light bulb glass shell red is more pure, red and infrared can penetrate, yellow light and other miscellaneous light is filtered out, so the naked eye visible light color will be more red.

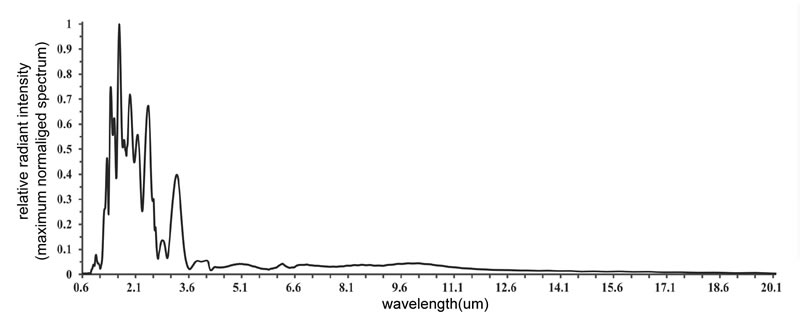

- Spectrum diagram compassion.

comparing the spectrum chart of the roasted red bulb and the natural red bulb, the infrared energy both peak in the infrared wavelength range (infrared wavelength between 0.76 and 1000um), in the wavelength 3.1-3.6 micron and 2.6-3.1 micron, the natural red light bulb is relatively higher than the roasted red light bulb radiation peak. Generally speaking, the longer the infrared wavelength, the more obvious infrared thermal effect.